The Facility Equation: What’s Driving Facility Change for Canadian Manufacturers?

Canadian manufacturers are under pressure from inside and out. Whether it’s expanding capacity, improving efficiency, or increasing resilience, the question isn’t just “Should we relocate?” It’s more complex: What’s the right facility strategy for our future?

At Enginuity, we’re helping clients face these decisions head-on, and what we’re seeing across the country is clear. Facility planning is not just about space. It’s about workforce, energy, equipment lead times, policy, supply chain, and capital strategy – all at once.

Why Facility Strategy Is on the Table

Industrial plants rarely grow according to plan. Lines get added. Processes shift. Utilities get maxed out. These incremental changes often outpace layout logic, code compliance, or infrastructure capacity. Eventually, the facility itself starts holding the operation back.

That’s when the bigger questions arise:

- Is expansion viable or are we boxed in?

- Could relocation unlock better logistics or cost advantages?

- What are we missing in the current setup that’s costing us in ways we don’t see?

What’s Driving Facility Change in Canada?

Beyond the physical realities, broader pressures are pushing Canadian firms to re-evaluate their assets:

- Industrial land and lease rate fluctuations, especially in major hubs like Vancouver and the GTA

- Aging or inflexible infrastructure that limits automation, layout optimization, or energy performance

- New trade and tariff policies, reshoring incentives, or “Buy Canadian” pressure changing supply chain models

- Decarbonization and ESG requirements, especially in manufacturing, food, agri, and resource-intensive industries

- Demand for supply chain resilience, reducing reliance on offshore processes or long-haul inputs

Whether it’s internal capacity or external pressure, most clients are now asking: are we in the right place, doing the right things, in the right way?

There Is No One-Size-Fits-All Answer

Facility strategy isn’t a yes/no or expand/relocate equation. It’s a multi-variable problem involving:

- Operational bottlenecks

- Workforce availability and commute impact

- Utilities and power reliability

- Permitting and code changes

- Real estate constraints

- Future production strategy

- Business continuity during upgrades

At Enginuity, we help clients step back from the tactical (e.g. “Where can I fit a new line?”) to look strategically at the bigger picture: “What facility model will best support our business in 5–10 years?”

Getting Clarity: Structured Planning Comes First

That’s why feasibility studies and phased planning are at the core of what we do.

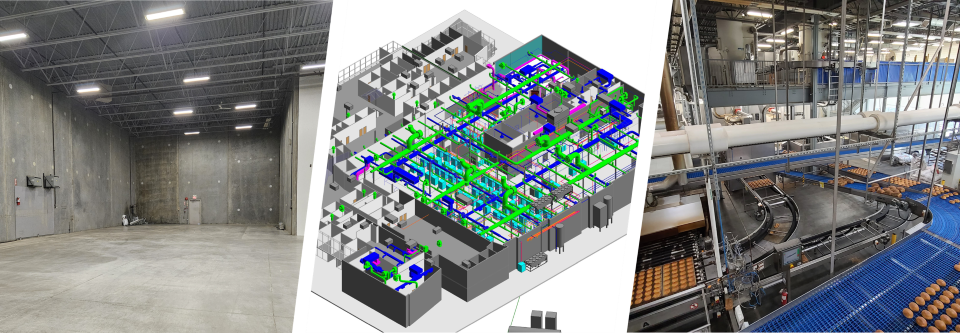

We begin by mapping your current state (layouts, constraints, workflow, code gaps) and evaluating future state options across multiple areas: space utilization, structural and utility loads, capital cost, constructability, permitting timelines, and production disruption.

In one recent case, a major manufacturer asked us to compare an internal expansion, an adjacent site development, and a full relocation. Through structured concept planning, we delivered a risk-weighted comparison across all three, helping their executive team confidently make a long-term investment decision that aligned with workforce retention, procurement strategy, and facility goals.

Design + Delivery: Choosing the Right Execution Model

Once the path forward is clear, how you execute it matters just as much. Enginuity helps clients select and manage project delivery models tailored to their risk tolerance, timeline, and internal capacity:

|

Model |

Ideal For |

|

Design-Bid-Build (DBB) |

Maximum control over design and cost transparency; preferred for code-sensitive, complex, or process-specific environments |

|

Design-Build (DB) |

Speed and simplicity with contractor-led coordination; best when scope is simpler or fixed and owner bandwidth is limited |

|

Construction Management (CM) |

Phased or multi-trade work with early input from builders; common in brownfield or retrofit projects |

|

Progressive Design Assist (PDA) |

Collaborative design with builder and trades insight, while maintaining owner control; ideal for complex or uncertain scopes |

No single model is “right” – but one will be right for you. And we’ll help you find it.

Permitting, Policy & Public Funding

Beyond the walls of your building, municipal and regulatory considerations shape the entire project timeline. From building code updates to environmental review, from CFIA compliance to city zoning, Enginuity helps you get ahead of the permit curve.

In many cases, our clients also benefit from funding mechanisms, grants, tax incentives, and workforce development programs available at the local, provincial, or federal level. We work with economic development offices and specialists to identify and unlock these supports.

A Word on Timing

Permits, approvals, design, procurement, and construction are all time-sensitive and often delayed by factors outside your control. But the longer you wait to start, the longer your operation may be underperforming. Equipment lead times for process or auxillary equipment like switchgear, HVAC units, or gensets can be 6–12+ months. Starting early doesn’t mean moving fast, it means moving smart.

How Enginuity Supports the Journey

From early-stage feasibility to construction-ready packages and project oversight, Enginuity supports Canadian manufacturers in:

- Facility strategy and concept planning

- Site assessments and code reviews

- Utility and facility audits

- Mechanical, structural, and electrical design

- Regulatory navigation

- Project management and execution planning

- Acting as your technical partner

We understand the complexity, and the opportunity, of industrial facility change. Whether you’re navigating capital investment planning, dealing with constraints, or preparing for long-term growth, we help you move with clarity and confidence.