Facility Layout & Design

In an industrially classified facility, an innate understanding of the process flow operations is of relevance to the overall facility planning. Where traditionally architects are concerned with human flow and occupancy, Industrial architects focus on the integration of process flow and equipment layout, along with operator and human flow to ensure well operating and efficient design of a manufacturing facility or terminal.

In combination with complex architectural and code requirements, industrial plants and manufacturing facilities require the integration of essential process and facilities engineering (mainly material handling/flow, process equipment, electrical, and mechanical) and regulatory compliance. This is essential to the early development stages of a project, as having a global view of all the disciplines and requirements forms the direction and foundation of a project and scopes of design and construction to follow, to achieve best results by allowing the following:

- Meeting corporate and regulatory requirements

- Realistic understanding of possible outcomes, with required scope and capital

- Understanding the space, property and facilities required

- Having cost estimates, budgets, and schedules

- Meeting schedules, budgets

- Handing off an Optimized and well operating facility to operations

Facility Planning

Whether your project is greenfield property development, requires a custom building, or expansion/ retrofit of your existing property, we can plan the design and development of the facility.

- Site Master planning

- Process Flow Development & Diagrams

- Plant throughput requirement & projections

- Space allocation requirements (Receiving, processing, utilities, warehousing, office space, etc.)

- Space Specification & Site Selection

- Integration with real estate experts, landowners, authorities having jurisdiction

- Operator / shift load requirements

- De-bottlenecking & Optimization studies

- Due-diligence audits

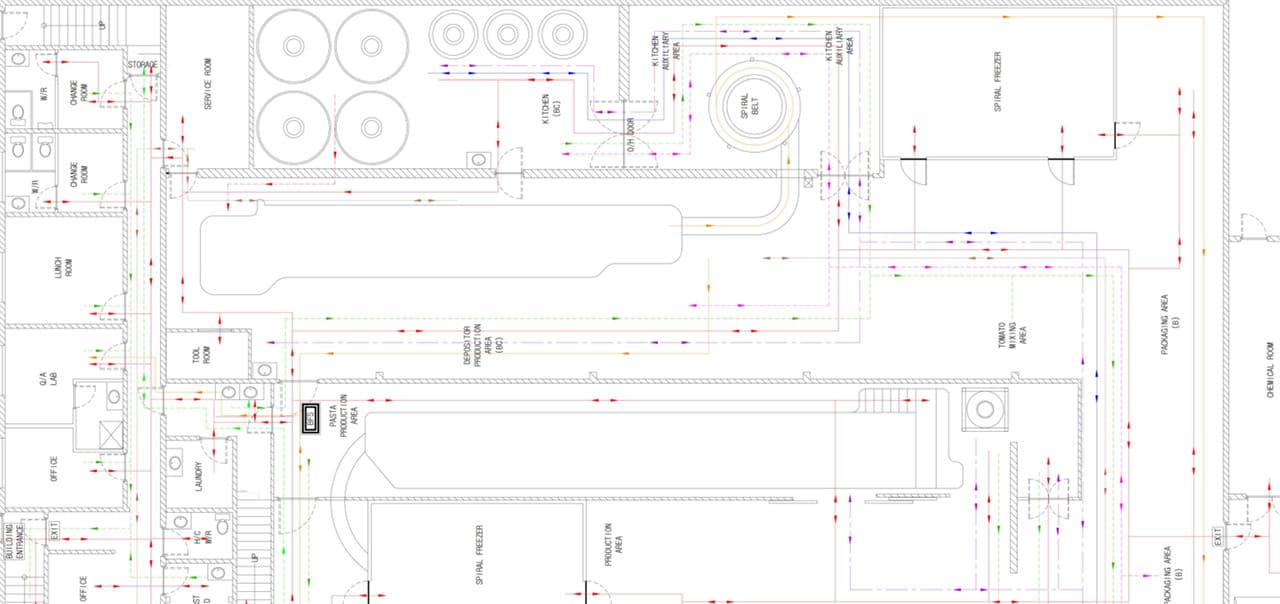

Site & Plant Layouts

Our site & plant layout team works closely with our projects team and other project stakeholders to develop and design of layouts for sites and facilities. The deliverables at this stage form the basis for permits (TI, Building, Environmental, etc.), cost estimation, project scoping, and engineering design.

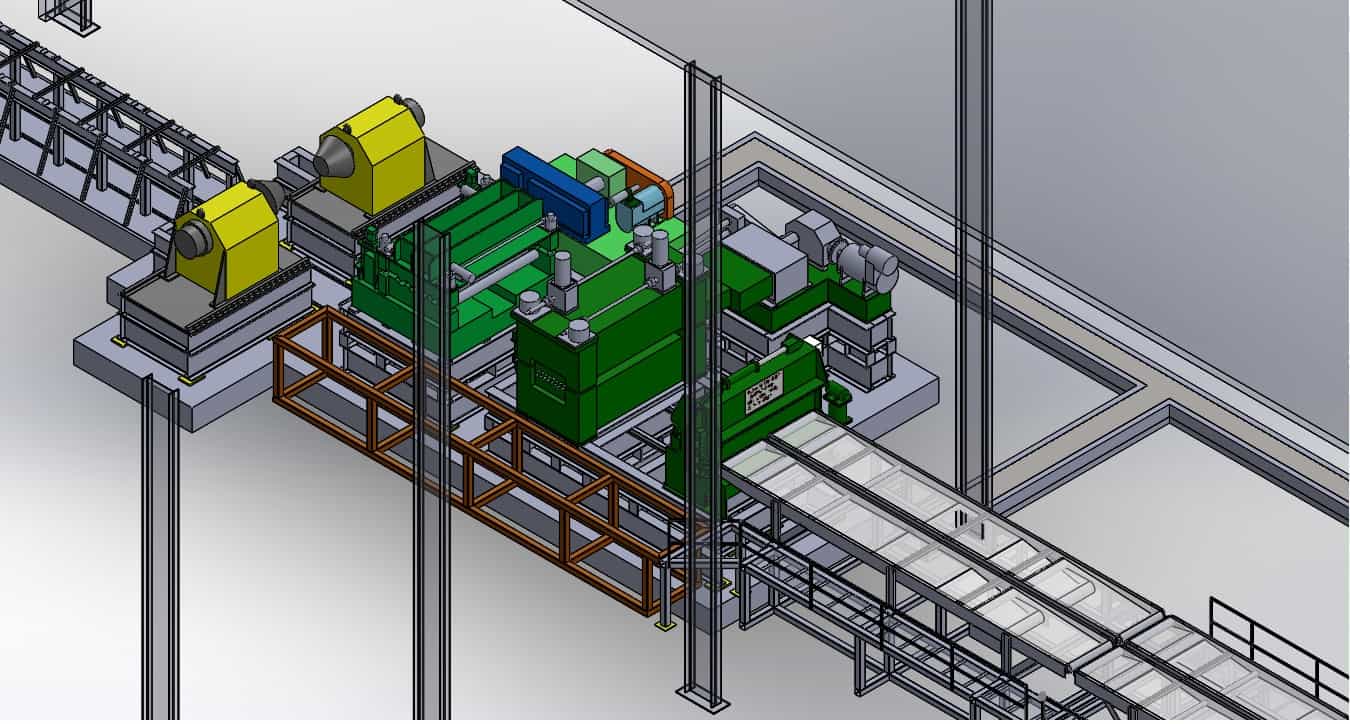

Our team uses 3D Modeling and BIM software to produce:

- Site Plans

- Building & occupancy classification

- Line & Equipment layouts

- Spaghetti diagrams

- Site Safety Systems

- Plant & Facility layouts

- Gaps analysis on Site Services & Utilities

- Equipment Specifications

- Liaison with OEM’s and vendors

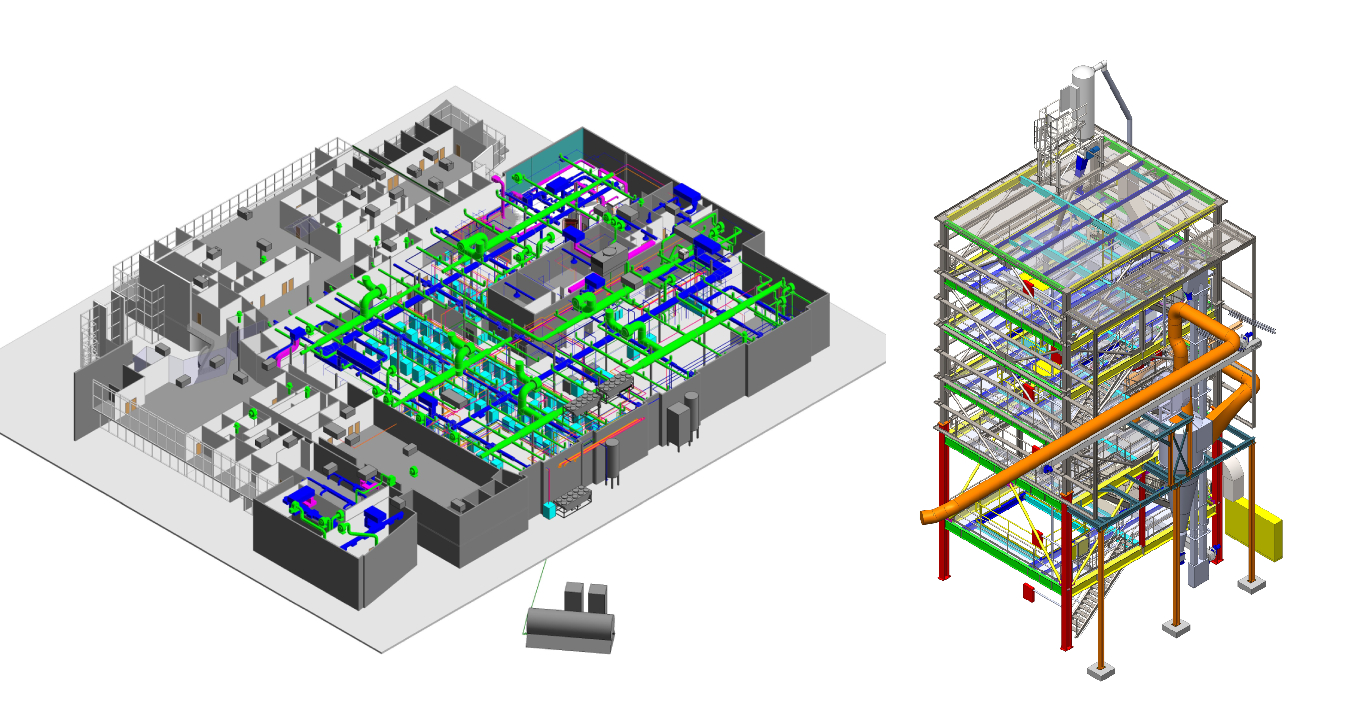

Building Information Modeling (BIM)

Why have 3D BIM performed at your facility?

- “As-builts” of Existing (Level of Detail – LOD – 200-500)

- Capture current state of facility for reference in all future uses – capital expansions, maintenance

- Retain up-to-date as-builts through design and construction

- Significantly reduce the cost of future expansion/modification plans

- Brownfield Modifications, Expansions, Tenant Improvements

- Clash detection (equipment, piping, structural steel, etc.) reducing costly re-design

- Drastically improves the effectiveness of design reviews (30%, 60%, 90%)

- Simplifies the process of design changes

- Reduces the necessity and dependence of site visits

- Multidisciplinary design, coordination, and integration for cohesive constructable models, issued for construction drawings, and shop drawings

- Assists OEM and Vendors

Rail Engineering

Our rail team works with our site development and project team early on as, on many industrial projects, the rail layout and requirements dictate the final site and facilities plan. Our team offers:

- Site and Operational Requirements Assessment

- Traffic Analysis for expected volume, car types, load and transfer weights, switching and spur requirements

- Geometry and Alignment design with respect to operations, design and service provider standards, curves, elevation changes for efficient and safe operations

- Track layout, switch placement, interlocks, crossings

- Loading, Unloading, Distribution Systems for bulk, liquids, transload facilities, etc.

- Interface design with respect to building, loading/unloading and other infrastructure, product delivery systems

- Civil loading and drainage design

- Construction and Materials Estimations for Execution

- Compliance with Regulatory and Authorities Having Jurisdiction as well as operational plans

- Detailed Design Packages for Construction

Code Consulting

- Certified Professional Services

- Code interpretation

- Consultation & design to various applicable codes

It’s best to meet us before you need us.

Let’s meet so we can offer you consultation on your needs.